Product Details

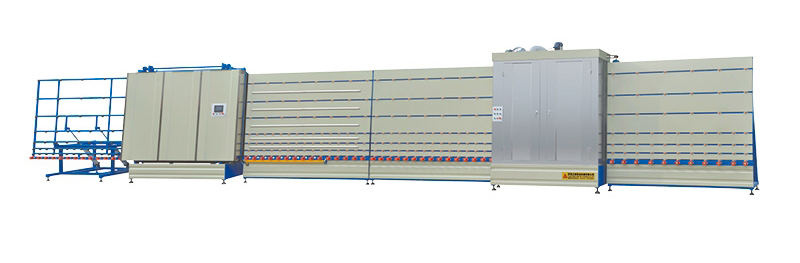

Vertical insulating glass flat-pressing production line is composed of glass transporter, automatic glass scavenging dehydrator, glass inspection transporter, automatic aluminum frame locating machine, glass flat pressing, glass reversible transporter, binding machine, butyl extruder machine, butyl extruder machine, bicomponent rubber-beating machine, molecular sieve bottler, and rotary rubber-spreading machine.

The production line is composed with PLC programs and has adopted advanced Austrian technology and flat press mode which is quite popular in the world in the production of hollow glass. The automatic flat press machine has a unique designation of two boxes (the box in the front is extracted to a vacuum state, the box in the back is responsible for providing driving momentum with floating air) to enable the two pieces of glass binding into one in one time.

It is also suitable for producing hollow glass of different sizes, shaped hollow glass and glass curtain walls and three-layer hollow glass.

Technical Parameters

*Max. glass size: 1800×2500mm

*Max. working speed: 45m/min

*Min. glass size: 540×280mm

*Electrical power: 15kW

*Cleaning glass thickness: 3-12mm

*Overall dimension: 15900*2350*2950mm

Online consulting

Related Products